A relic from the 1940s or '50s, this is the Canadian version of a Sears Craftsman machine bearing the same model number.

The above photo shows it part way along to restoration, along with a cabinet stand that I've made for it. Here are views of the I.D. plates.

Simpson's was the Robert Simpson Co., which partnered with Sears in 1952 and sold the Craftsman line of tools in Canada. The machine pictured here would later have been branded Craftsman, as it always was in the USA.

I picked up this item off Kijiji. Much of it is in pretty good condition, but there are some flaws to be corrected, and some missing pieces that I'll have to come up with replacements for. Permit me to give you a tour of the machine as it currently stands.

The Lathe Bed

Aside from the grime, splotches and discolouration, this is a thing of beauty.

It's undamaged. The machined ways exhibit only the slightest bit of surface rust. The structure has five cross-ribs underneath, so it's a sturdy, rigid affair that's truly fit for its duty. It attaches to a work surface by way of three 5/16" bolts.

The Tailstock

The tailstock's position clamp, ram and handwheel are complete, but there are three items missing from the tailstock:

- The ram's 5/16"-18 locking screw is supposed to have a handle attached to its head, so that a wrench is not needed. I'll fabricate a knob-headed screw from a suitable knob that I have on hand, and some threaded rod. I'll have to machine a dog point on the end of the threaded rod to make it proper.

- The tailstock's centre is missing its centre. The centre is an MT1 shank with a hollow end that's meant to accept a small, tapered centre point. I can get an MT1 dead centre from KBC Tools & Machinery. Busy Bee lists an MT1 live cup centre on their website. I'll probably end up getting both. A 1/2" drill chuck for the ram would be nice to have as well.

- The lathe would have originally come with a 3/4" wrench for tightening the tailstock's position clamp, and the tool rest's banjo. That's long gone. I'll get a low-end 3/4" combination wrench from Princess Auto to replace it.

It's a sturdy 8" tool rest in good condition.

The Headstock

And here's where all the real trouble resides.

There's quite a lot to tell about this item; I scarcely know where to begin. I'll just list the headstock's features/characteristics/problems in no particular order.

The Pulley And The Indexing Feature

The pulley in the photo is a standard replacement 4-step pulley with a 3/4" bore. The original pulley was missing from the lathe.

The large diameter face of the original pulley had 36 holes in it which, in conjunction with a spring-loaded, retractable pin, provided the lathe's indexing feature (an index stop at every ten degrees). Needless to say, the indexing feature is now inoperative, although the spring-loaded, retractable pin is fine. I have an idea how I might recreate the feature with a separate indexing disc. I'm not certain that it will be doable. We'll see.

The Bearings

The bearings are 3/4" bore x 1" O.D. x 1" long porous bronze sleeves. They're actually not in bad condition for bore size and roundness, but the inboard bearing has some nasty looking scoring in its bore. I have replacements on order -- I'll replace both bearings.

For a thrust bearing, the lathe originally had a ball-thrust bearing that apparently resided inside the headstock casting at the outboard end. That bearing is missing. I'll replace the thrust bearing's function with a collar and a bronze thrust washer at the inboard end of the spindle. I won't be using the collar that's in the above photo -- I'll get a more suitable steel collar from Princess Auto.

The Spindle Nose

It's not threaded. I believe that a later version of this lathe had a threaded spindle nose, but this early machine just has a flat for set screw attachment of an accessory like a face plate. Good luck finding a face plate to fit such an arrangement. I'll have to see if I can fabricate a face plate somehow.

The spindle's bore takes an MT1 taper. A spur centre came with the lathe, so that's taken care of.

The Spindle

It's remarkably undersize in diameter -- it's 0.741". (Nominally, it should be 0.750".) That mystifies me. It makes for a pretty sloppy bearing fit. It works, but the bearings have to be generously oiled, else they're prone to run noisily.

The spindle's undersize condition also made for a lot of radial pulley run-out with a standard, 3/4" bore pulley installed. I solved that problem with a serendipitous piece of shim stock, and the pulley now runs reasonably true.

The Headstock's Front Cover

There isn't one, though there's supposed to be. The headstock would originally have had a sheet metal cover for that gaping opening in front. I'll have to fabricate a replacement; that'll be a bit of a challenge.

The Paint

It's pretty old and tired and beat up looking. The best I'll be able to do for a near match to the original will be to repaint it Tremclad grey. That'll be a gloss finish. I'd rather it be a satin or matte finish, but those don't seem to be available in a suitable enamel.

Anyway, there's what I have to work with. On with the restoration.

Motor Wiring

It's pretty straightforward. The Home Depot has everything that's needed, except for maybe a 5/16" cable clamp and 1/4" spade terminals -- I had those on hand.

I dislike extension cords, so I fit out machinery with power cords of a decent length. I find that four metres of 16 AWG SJOOW line cord is ideal for fractional horsepower installations. In this instance, after subtracting the length of cord from the switch to the motor, I was left with a power cord length of about 11 1/2 feet.

Nothing special in the way of a switch is needed for fractional horsepower motors. A common Leviton 15A toggle switch serves nicely.

Note the cable clamp in the second photo above. I was taking no chance that the motor's power cord might ever meet the v-belt.

The Motor

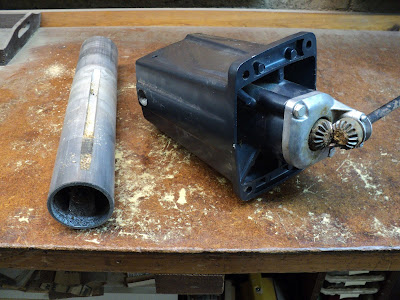

I'm using a 1/3 hp furnace fan motor. 1/2 hp is ideal for a typical wood lathe, but 1/3 hp is adequate. No one is going to be turning porch columns on this lathe.

A TEFC (totally enclosed fan cooled) motor would be nice, but those are costly items. The motor shown in the above photo will do.

- - -

So there we have the current state of the lathe. This blog post is getting rather long, so I'll start a new post for the restoration information

# # #

# # #